The high CO2 concentration of cement flue gas makes for an easier and less expensive separation.

Opportunity

The cement industry is a large and growing industrial sector. An average cement plant produces about one million tonnes/year of cement and the CO2 emissions average between 0.8 to 1.0 tonnes of CO2/tonne of cement produced. The CO2 emissions from the cement industry accounts for over 5% of total global emissions. Unlike wind or solar, which offer a zero-carbon source of electricity, there is no “renewable” equivalent for cement. The only option for reducing carbon emissions from cement plants is with carbon capture and storage.

Membrane Solution

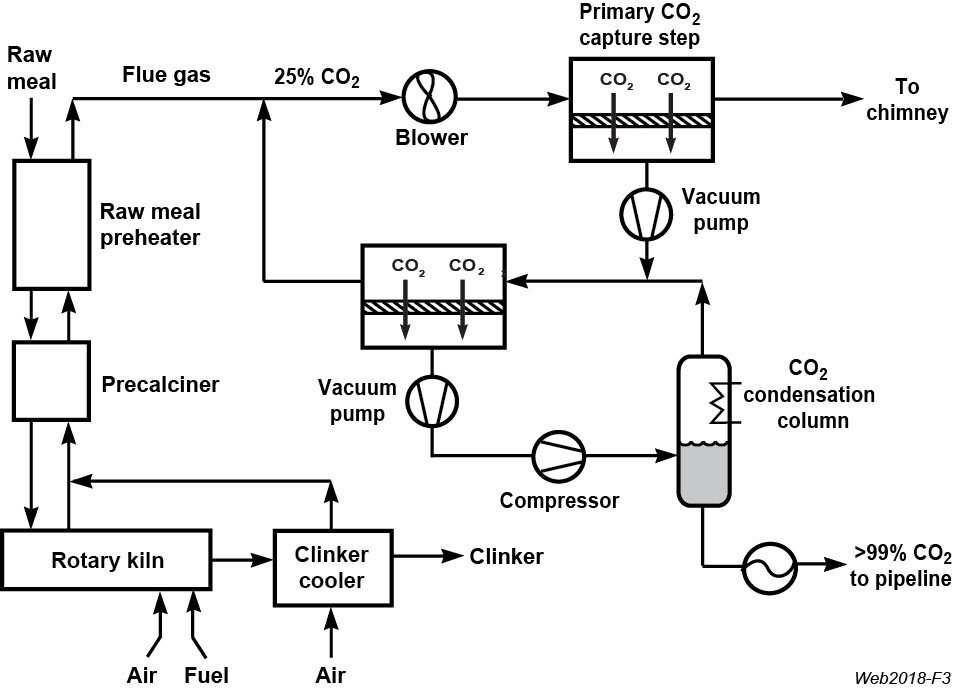

MTR’s capture process for cement plants has the same general form as our process for coal fired power plants. However, because the flue gas has a higher CO2 concentration, the energy consumption per tonne of CO2 captured is reduced and the cement capture plant only requires half of the membrane area. Because membranes do not require steam to drive the separation, there is no need to add a new natural gas or coal fired boiler to service the capture plant.

Benefits

- No use of chemicals, so no chemical handing or emissions issues

- Modular membrane units are scalable, compact, and easily configurable for retrofit applications

- Simple and passive operation

- Fast response time and excellent turn down

- Low maintenance and operator requirements

- No steam use; minimal/low cooling water requirements/use

System Performance

- System size: 1 tonne CO2/day and up.

- CO2capture rate up to 90%, most economical ~50-60% capture rate.

- Produces high purity liquid CO2

Application Options

- Coal fired power plants

- Natural gas fired boilers and turbines: NGCC, OTSG, CHP plants

- Fossil fueled industrial plants: cement, steel, waste-to-energy, refinery

- Biogas sources: digesters, fermenters, and landfills