Key Publications and Presentations:

VaporSep-H2™ is a simple system offering economical recovery of hydrogen from the syngas purge.

Opportunity

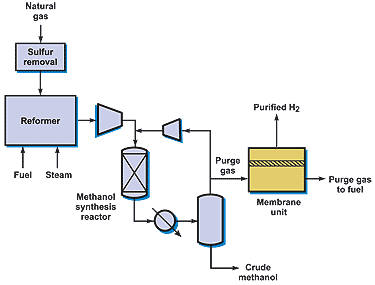

In methanol production, synthesis gas is generated by reforming natural gas with steam. The synthesis gas is compressed and then reacted to form methanol. Unreacted syngas is recycled to the reactor. Since the normal ratio of hydrogen to carbon in the synthesis gas is greater than 2 ( the value required for methanol synthesis), excess hydrogen is removed by purging a hydrogen rich stream from the reactor loop and sending it to fuel.

VaporSep-H2™ Solution

Recovery of hydrogen from methanol plant purge gas

If there is a use for hydrogen elsewhere in the facility, MTR’ s VaporSep-H2™ membranes can be used to recover relatively pure hydrogen from this purge gas.

Benefits

- Recovers useful hydrogen from methanol plant purge gas

- Requires no additional rotating equipment

- Easy to operate, passive system

- Ambient temperature operation

- Simple installation with skid-mounted construction

VaporSep-H2™ system for hydrogen recovery from methanol plant purge gas

System Performance

- Complete skid-mounted unit includes all necessary instrumentation and controls

- Typical size: 6m (L) x 3m ft (W) x 2.5m (H); 6000 kg

System Description

- Typically 80% of purge gas hydrogen recovered

- Payback is 6 to 12 months